| Machine: |

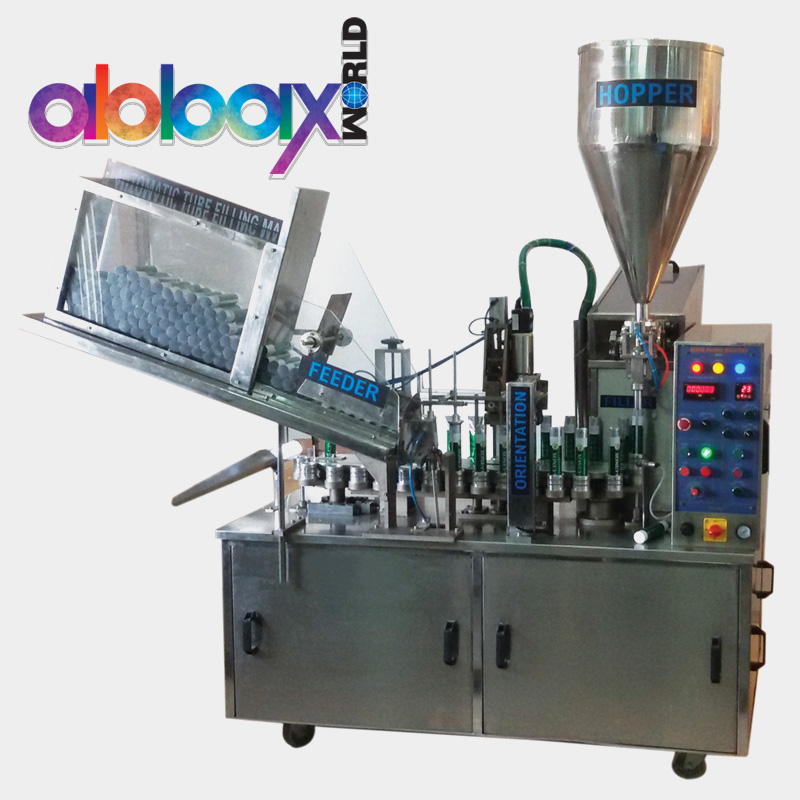

Fully Automatic Linear High Speed 24 Stations (Single Hopper Double Nozzle)

Tube In Feeder Cassette Device Attached Lami/Plastic/Aluminum Tube Filling, Sealing And Coding Machine. |

| Model: |

ABBAX-120 |

| Product, To Fill & Seal: |

Ointment / Cream into the Lami/Plastic Tube |

| Respect to tube Dia. & tube height maximum: |

Tube Diameter max. 40mm, & Tube height max. 200mm. |

| Filling device: |

Positive suction & displacement complete SS-316. After each filling session a control on tailing is achieved by a pneumatic cut-off system, along with filters, that cleans the nozzle of the excess sample. |

| Syringe Pump Insert for Filling: |

(5 Gms. to 30 Gms.) or (30 Gms.to 100 Gms.) or (100 Gms. to 200 Gms.) Any one of the three sets will be provided against requested specification in your order. |

| Filling Capacity: |

Machine is suitable for 5 gms to 200 gms with inter changeable Syringe pump. |

| Product , Contact Part: |

S.S-316. |

| Hopper: |

Hopper of 60 Kg capacity(Working Volume 52 Kg). |

| Filling Volume setting: |

Cam for Valve operation as well Fine Tuning adjustable Control System. |

| No tube - No Fill Device: |

Activate Sensor with Electrical Logic Control system. |

| Filling Accuracy: |

± 1%. |

| Output per Minute: |

Up to 120 Tubes/ Min. In Single Hopper Two Nozzle (depending on the Fill sizes). |

| Indexing Device: |

Indexer Manifold . |

| Auto tube in feeder: |

Cassette Device System with Four Cassettes One Tube Size will be provided. |

| Change Part : |

Syringe Pump Housing of 30gms to 100 gms, Two Cassettes , Tilting Cam, Feeding Con, Holder, Filling Nozzle, and Heating Adopter, of Removable type suitable for any one-size of tubes. With basic machine. will be provided |

| Tube Orientation Device: |

Top Drive (Photocell Unit) Make Std. and Stepper Motor & ‘I’ Mark Sensor DETALOGIC Make. At the separate station. |

| Lami / plastic tube heating device: |

LEISTER or BAK Swiss Make, with suitable for Blower 0.35 HP. BLOWTECH Make. And hot air tool adopter jacketed water cooling systemAttached,at the separate station. At the separate station. |

| Lami / Plastic Tube Sealing Device: |

Pneumatics operated. Jacketed water cooling System Attached, In sealing & coding where in the tube is pressed & sealed and then batch coded. With metal stereos coding Letter punch (female type 0 to 9, one set). At the separate station. |

| Trimming device: |

Pneumatics operated. At the separate station. |

| Tube ejection: |

Automatic Filled Tube ejection at separate station. |

| Machine System Description: |

Empty Tube Feeding, ‘I’ Mark Orientation, Filling, Sealing, Crimping, Coding and filled Tube Ejector Automatically. |

| Machine security: |

Overload clutch for centering and micro switch cut-off system. |

| Control Panel: |

Necessary functional features like emergency stop, re-set, inching, and user friendly, Electrical logic system are standard with the machine, with interlock & indication on the main operator’s of panel to Electrical logic Control. |

| Motor: |

1.5 HP; 1440 RPM 3Ph. 440V AC. Hindustan Make. |

| Gear Box: |

Suitable Gear Box Ratio 30-1 Make PREMIUM with Separate Drive. |

| Production speed control: |

Variable speed control Suitable VFD Drive makes DELTA. |

| Production Counter: |

Activate Sensor with Electrical Logic Display 6 mm. Size, 6 Digital Counter. |

| All Pneumatic components: |

FESTO Germany Make. |

| Machine Entire frame: |

Fabricated in Machine Entire frame Mild Steel With Powder Coated &will be in hard Chrome plated & duly ENP coated and all othercams and levers will be in graded casting & alloy steel. With all side covers in S.S.-304. |

| Power Input: |

2-5 kW. 3 phase. |

| M/c. Dimensions : |

(L) 2640mm x (W) 1080mm x (H) 2450mm. |

| M/c. WeightApprox: |

Overall Wt. Approx. 1200 Kgs. |